DEVELOP YOUR DESIGN TO A LEVEL OF DETAIL NECESSARY TO WORK OUT A CLEAR, COORDINATED DESCRIPTION OF ALL ASPECTS OF THE PROJECT. DERIVE ALL CONSTRUCTION, PERMITTING, AND BUILD DRAWINGS AND DOCUMENTATION. DETERMINE FINAL BUDGET.

How to Build a Shipping Container Home:

Conceive It. Focus It. Action It.

Focus It.

By now, you should have a good sense of your site, your budget, and a rough conceptual design for your shipping container home. You should also be well acquainted with containers. If not, have a look at the RSCP™ CONCEIVE IT section for preliminary and general information for the build, look at the Everything About Containers link for detailed info on shipping containers.

I. Designing Your Shipping Container Home

Foundation

Finalize building location on site. Remember, flat sites are best as they require minimum excavation and grading. If you are planning a build which consists of more than one container, you should talk with an engineer or contractor early. Foundation costs are potentially very expensive, especially if the bearing capacity of the soil is poor or land substantially sloped.

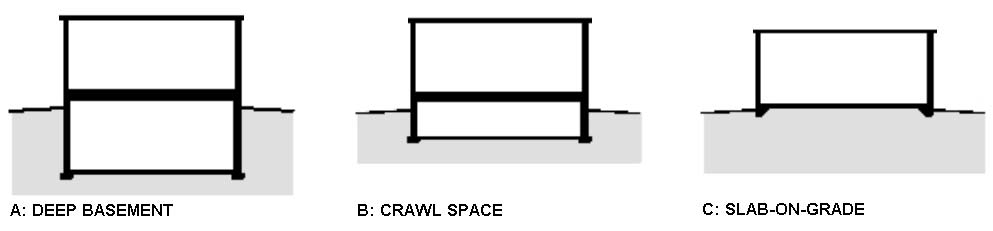

The three basic types of foundations are - full basement, crawl space, and slab-on-grade.

The Shipping Container House Foundations link in the Reference section has more information on foundation options and design.

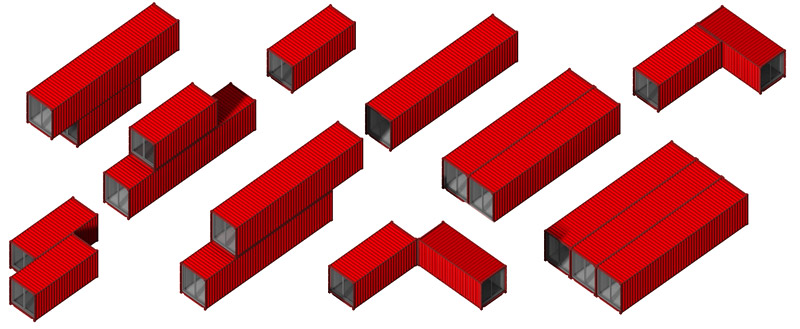

Shipping Container Home Massing Examples

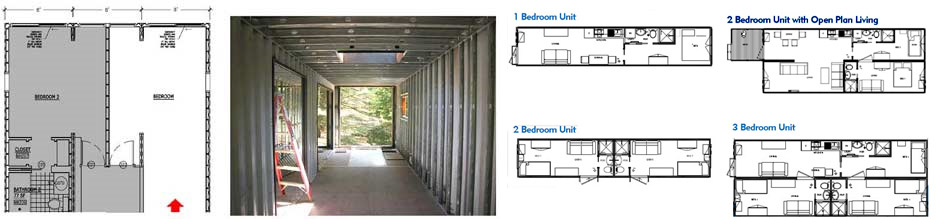

Shipping Container Home Floor Plans and Interiors

See the Shipping Container Home Floor Plans section for example floor plans.

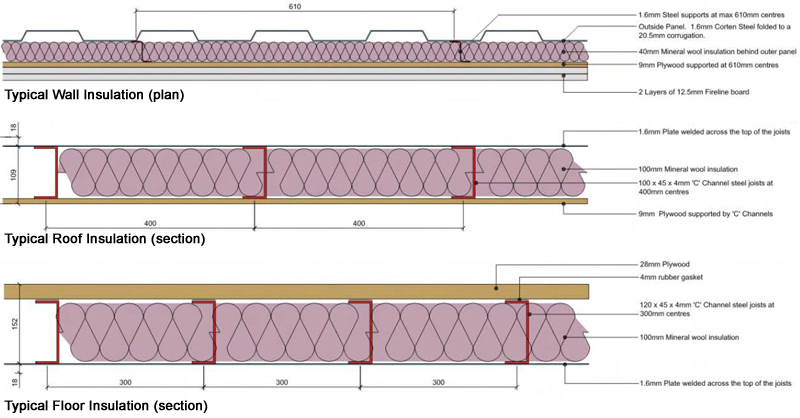

Core Envelope

The exterior walls, ground floor, roof, and glazing make up the core envelope of a building. Energy code compliance and your site's location, thermal zone, and climate factor strongly here and will determine insulation requirements. Keeping the building warm in the winter and cool in the summer with minimal mechanical system help will do much to drive down monthly utility costs. The conceive it section has information on passive vs. active heating and cooling strategies. These should be reviewed prior to developing/detailing the core envelope. The Passive Solar Design Issues link in the Reference section has good preliminary information on passive design issues to consider while designing/detailing your shipping container home's core envelope.

The US Department of Energy has a fantastic tool (REScheck) to simplify and clarify code compliance with the Model Energy Code (MEC), the International Energy Conservation Code (IECC), and a number of state codes. You input the square footage of each core envelope element (wall, roof, slab, etc.) and project location. This will determine the binding energy code and allow you to play with different R values (insulation levels) until the envelope design is in compliance and thereby setting the required R-values. Even if your project is small or not subject to energy code compliance, the REScheck exercise is worth the time.

The R-Value Table in the Reference Documents and Details section to the right that has different assembly R-values. Once you know the required R-values for the core envelope elements you can begin detailing. For illustration, consider a cold climate that requires an R-30 value for exterior walls. This could be achieve with batt (R 3.25 per inch ~ R30 would require 9-10"), foam panels (R 5 per inch ~ R30 would require 6"), and standard spray foam (R 6.75 per inch ~ R30 would require 4.5"). The Insulation link in the Reference section has more detailed information on insulation requirements, assemblies, and types.

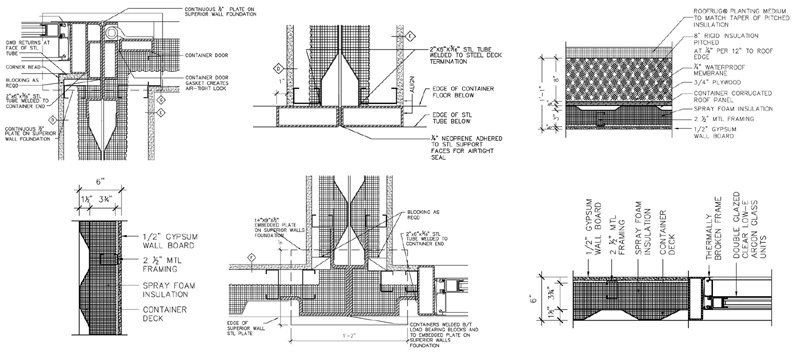

Plan and Section Details

Typical plan and section details including floor, roof, walls, glazing, and container connections can be viewed at the Shipping Container Plan and Section Details link.

Utilities and Mechanical

Utilites -Water supply and sewage, electricity, natural gas, and telecommunications/fiber optics.

Mechanical - Air circulation and temperature regulation.

II. Drawings and Documentation

The drawings of a typical home construction project evolve through each of the design milestones - Conceptual/Scheme Design, Design Development, Permitting, and Bid/Construction Documents. Conceptual/Scheme Design and Design Development drawings are important to develop the necessary design, floor plans, elevations, and the budget square footage takeoffs. Typically, they are a communication tool between the designer and client as they vet through the design of the home. If you are the designer, you will develop these drawings loosely yourself as you outline/document the design. You can use hand sketches or utilize one of the many consumer modeling and drafting applications. But, they are for your own reference and not necessary for filing.

Permitting Drawings

If for what every reason you are not subject to any building department/jurisdictional approval (very rare) you will not need to assemble a Permitting Drawing set. If you are, which is most cases, first thing to do is call the building department and get a permitting submittal checklist. Things typically required will be plans (site, foundation, floors, and roof), elevations, land survey, water treatment (septic and run-off), energy code compliance, structural drawings, and soils report. Also make sure to check which of these documents will need to be stamped by a licensed professional.

Bid and Construction Drawings

Contract Documents. They should include drawings and specifications for all components and systems of the building. A complete set of Contract Documents provides a comprehensive, fully coordinated set of construction documents and specifications that the contractor uses to determine a guaranteed maximum or lump sum price, obtain necessary permits, coordinate with factory for modular components, and construct the project. Even if you are planning on taking on the construction yourself or managing the project through sub-contractors, you should put together as detailed and extensive set of construction documents as possible. Putting the construction documents together will help tremendously in understanding the design and verifying the projected budget prior to construction.

III. Build Strategy

Regardless if you are going to bid the project out to general contractors (GC) or build yourself, you should speak with as many potential GC's as possible throughout the design process. Having done this prior to bidding the project will do three things; help get accurate pricing for budget development, assemble a list of general contractors to bid competitively for the project (if you are not building yourself), and problem solve the design.

If you go the GC route, there are fundamentally three project delivery methods: Design/Bid/Build, Construction Management, and Design/Build. The different methods are distinguished by the way the contracts between the Owner, the Architect (if there is one), and the Contractor/Factory are formed and the technical relationships that evolve between each party inside those contracts. Typically, there is no single "best" method for all projects, and no method delivers fastest, cheapest, and highest quality simultaneously. What distinguishes each is the amount of design information and drawings available prior to construction and whether the build price is fixed or relative to actual costs.

The design and manufacturing of shipping container homes is a viable alternative to conventional construction for many reasons, but despite a strong showing of successful container projects, building with shipping containers is still in it's early stages. From the design perspective, there are many design entities with "Kit" shipping container home offerings. These however, are very far from turnkey. Virtual none of the "design entities" have shop/manufacturing capabilities. The ones that do, have very small custom shops with limited output which is highly customized and high in price. From the manufacturing perspective, there are more and more factories/companies building with containers. Typically, they have a "stock" catalogue of very base shipping container home designs to purchase turnkey. Some can provide customized solutions (design to your specs), at higher cost points.

Ultimately, whether to hire a general contractor or build yourself depends on - the complexity of the project, your skill and/or experience in building, how much time you have to devote, expected level of finish or craftsmanship, and budget.

Link to the last RSCP™ Primer section ACTION IT here.

Focus It Checklist:

Foundation Design

Develop floor plans and elevations

Determine Structural Design and Container Modification Requirements

Envelope/Core Shell Detailing

Figure out Energy consumption

Investigate passive design moves to improve thermal performance

Interior Fit-out development

Prepare Mechanical and Electrical Design

Outline Material Specifications

Outline Lighting and IT Requirements

Outline Build Strategy (think about whether you are going to act as general contractor or a higher builder).

Outline Procurement Strategy (what level of container modification and fit-out will be done at factory and on site).

Prepare Construction Documentation (both Architectural and Structural)

Prepare Mechanical and Electrical Documentation

Finalize structural design criteria

Coordinate Preliminary Plan Review with building official

Coordinate documentation for manufactured components

Coordinate documentation for potential contractors

Prepare final specifications

Prepare final budget

How to Build a Shipping Container House:

Conceive It. Focus It. Action It.

Design Services and Help link here.