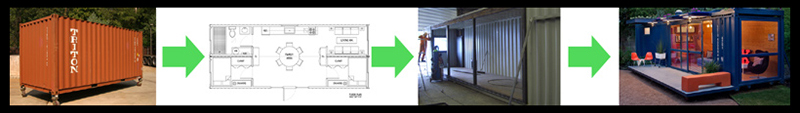

Introduction: Shipping Containers as Building Components for Home Construction

No two building projects are the same. Even with modular kit applications, variations due to location and climate, site factors such as grading and slope, and home owner preferences (to name a few factors) create substantial differences between projects. The RSCP™ Primer is built around the premise that there is no single perfect shipping container home design solution, and the most important thing in any home building project is preparation. Preparation, preparation, preparation. Ever hear the old carpenter’s axiom “measure twice, cut once”? Did we mention preparation is important?

The Primer has three parts –

There are “what to do” and “how to do it” articles for container home and non container home applications. Bear in mind, that a shipping container house is just a small steel building and much of the information/detailing of steel buildings (and wood framed as well) is applicable and relevant to shipping container home building as well. The Primer outlines and details the steps and stages required to turn recycled shipping containers into shipping container homes and buildings. Including (but not limited to) feasibility, budgeting, scheme design, technical hurdles, site concerns, foundation, envelope, modifying structure, passive enhancements, construction documents, and permitting. Many are looking to containers today for their building projects. Why? Because it is a good idea whose time has come. But is it right for your home project? RSCP™ can help you figure that out. Then help get it done with both overview and specific examples.

The RSCP™ Primer also provides worksheets to outline the design and execute your build. These are the Project Budget Worksheet, Square Footage/Surface Area Worksheet, Sourcing Worksheet, and Timeline/Critical Path Worksheet. You can request them in the Get Help section.

More general information on shipping container homes and architecture is available in the Shipping Container Architecture section.

Conceive It.

FEASIBILITY AND PRE-CONSTRUCTION ISSUSES FOR BUILDING A SHIPPING CONTAINER HOUSE.

Establish planning and design goals. Define and evaluate space requirements. Review benchmark standards, codes, and guidelines.

90% Of good architectural design is planning – knowing what you want from your home, what you can afford budget wise, and what the external factors (site, code, costs, etc..) are. Preparation is an important part of the design process. As you start to design yourshipping container home, the “limitations” brought about by site, code, and budget can serve to inform many of the necessary design decisions along the way. Being aware of these issues and how they could potentially impact (productively or negatively) the design and budget, will keep the design economical and efficient. And buildable.

Conceive It, or Pre-Design, is a critical phase where expectations are set, and budget ceilings determined. The primary objective is to establish a conceptual design (with input from design professionals, potential contractors, modular suppliers, and material/equipment suppliers) concurrently while a comprehensive budget and schedule are developed. This allows a true profile of scope, budget and risk to be understood and assessed early on.

‘Conceive It’ index:

- Before You Start

- Understand Site Issues and Passive Energy Potentials

- Create a Simple Floor Plan and Site Layout

- Conceive IT Checklist

Before You Start

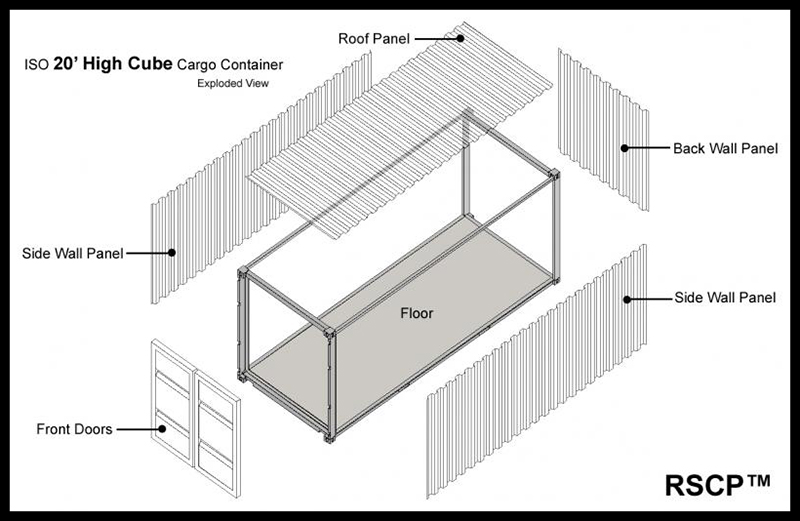

Look closely at shipping containers – photos, drawings, and if possible, go “tour” one. Walk around it. Stand inside it. Getting a sense of the actual size 1:1 , is very helpful in understanding scale and working floor plans. If you haven’t already looked at our shipping container information page “Everything About Shipping Containers“, follow the link here . Drawings with detailed shipping container structural components and terminology available here. Shipping container CAD drawings and models available here.

Know the relevant/binding codes you will have to contend with. Where you are planning to build your shipping container home dictates all requirements. Even if you are going to have a portion of the container structural modifications done off-site at another location, it will be your local building/planning department that will review drawings for conformance, issue permits, and conduct inspections. It is advisable to contact your local building/planning department sooner than later. Dealing with building issues everyday, they can be a great resource. You don’t have to go into great detail about building with containers. Mention it, but in passing. Focus the conversation on the fact that you are contemplating building a home with modular steel components and are looking into pre-construction issues. Ask if there are any planning/zoning restrictions, a maximum square footage for any building(s), a maximum height limitation, or maximum number of bathrooms. Most building departments (even lots of smaller ones) have websites with all relevant code information as well. At this point, don’t get too intimidated by the code or scrutinize it. Concern yourself instead with big picture issues. Like, can you build a house(s) on the land/site, and what is the maximum square footage you can build. It is also important to get a list of what drawings, permits and inspections, including fees, will be required. Find out what drawings must be professionally stamped as well. You should also check if their are any deed restrictions on your title. Some jurisdictions dictate zoning and planning in deeds, especially subdivisions.

It is worth mentioning here, that most states grant a land owner the defacto right to build a personal residence on their private land, regardless of binding local zoning or building code. However, this is dependent on financing and post occupancy issues. If you are going to finance (mortgage) any of the cost of the build, banks will require a certificate of occupancy (C of O). If you are planning on selling the land and house in the near future, you will also need a C of O. This is to protect the future buyer. To get of C of O, you must conform the building to all zoning and building codes.

Derive a rough order of magnitude project budget. Get the sticker shock out of the way at the beginning. When you’re building a house, you don’t want costs appearing from nowhere. Unexpected expenses in both construction costs and professional fees, are typical. Even to the best prepared. The only way to minimize the unknowns is do your homework. Possible required professional services are land surveyor, civil engineer (storm water management, grading, septic), structural engineer, architect, and mechanical engineer. Permitting requirements are a good indicator here (see above). You might also contact local architects who have built conventional but comparably sized projects in your area. A quick preliminary conversation with a good architect can give a sound picture of total soft costs. Also talk to potential contractors/builders, sub-contractors, and shipping container depots/resellers. Contractors can be an excellent source for pricing site portions of the project – including foundation, grading, bringing utilities to site, and septic. Researching/talking to shipping container depots can give a good sense of container prices and availability, but also local shop capabilities. It’s good at this stage, to get a sense of what level of container modification (and possibly interior fit-out) and at what cost can be done offsite. Welding on site, particularly on small projects, can be very pricey. Having as much of the container modifications done offsite is a good initial general strategy.

Without a building design , it’s impossible to fill out the budget. Again, focus on the big picture. Goal is to have at least line items in your budget for all potential costs (including both hard and soft costs). This will help tremendously as you begin to design and detail your shipping container home. Our RSCP™ Project Budget Worksheet is a good reference and can help get you started with the budget. Link to the worksheet is here. The budget will be a crucial document/resource throughout the process. Your project will be best served by continuous budget updates as you get more info and develop/focus the design.

Understand Site Issues and Passive Energy Potentials

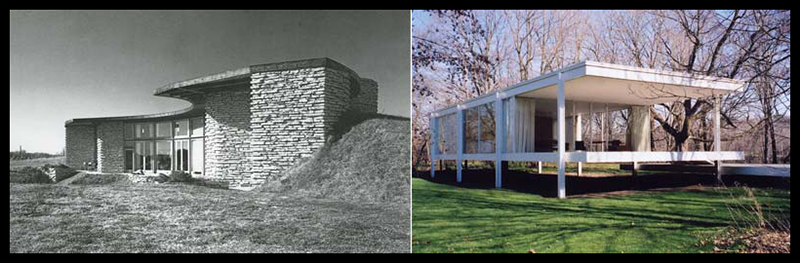

Passive vs. Active heating and cooling . At the risk of being too general, there are two types of building designs. Those that embrace the site, and those that impose themselves on the site. The house pictured above on the left is Frank Lloyd Wright’s solar hemicycle Jacob’s house. The house on the right is Mies van der Rohe’s Farnsworth house. Both are icon’s of 20th century modern architecture built/designed by masters. They are both comparative in size, use, and initial project budget. The maintenance and yearly energy expense for the two however, are substantially different. The contrast is due to the buildings’ different shapes, orientations, and wall/surface materials. The Jacob’s house design embraces the site. Through the use of an earth berm and orienting the building to the path of the sun, the house advantages passive heating and cooling strategies. These help control temperature and correlate to lower energy consumption. The Farnsworth house imposes itself on the site. Its orientation and open elevations create a seamless, transparent, and breathtaking flow of interior and exterior space. However, it’s a glass box that heats up quickly in the summer and is extremely drafty in the winter. Each building illustrates an extreme; the Jacob’s house highly passive, the Farnsworth house requires substantially more active heating and cooling. Each has its unique appeal and adaptability to container building and offer lessons to consider in the initial planning and conceiving of your shipping container home design and site orientation. As we look closer at detailing and core envelope issues for a container house design in the FOCUS IT section, we’ll return to these two model houses and passive design. Further preliminary reading is available at the Passive Solar Design Issues link. More detailed Insulation information available here.

Picking where to build on site is a crucial decision. There are many factors to consider including grade, soil bearing, existing landscaping, potential views, and proximity to easements/site boundaries/roads. Generally speaking, if soil bearing capacity is consistent throughout the site, flat/level areas are best suited. They require less grading/excavation, and allow for the most economical foundation designs for shipping container homes.

Landscaping and shading are very effective passive design strategies. When you consider where to locate your house/building on site try to take advantage of as much existing greenery as possible. The location of dense, coniferous trees on the elevation against the prevailing wind (usually west or northwest) may decrease heat loss due to infiltration and wind chill factor in the winter. Sites with deciduous shade trees can reduce summer solar gain if positioned properly on the south and west elevations of the buildings.

Views and privacy will also be important things to consider. Every site is different and has its own potentials. If you don’t already have a land survey of the site, it’s probably a good time to get one done. They’re full of relevant information and could bring things to your attention (like easements and utility access locations) that you’re unaware of. If you are lucky you received one when you purchased the land or will be able to get one from the record files of your building department.

Create a Simple Floor Plan and Site Layout

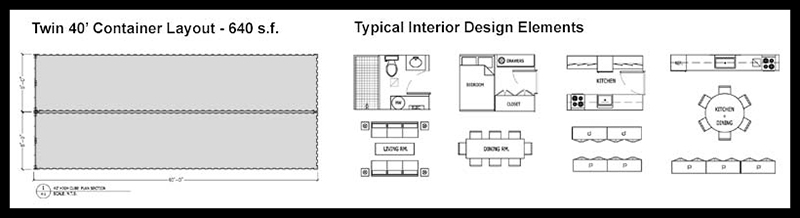

Time is the most important thing in life. Reviewing code and cold calling to get material pricing isn’t the best time you’ll ever have, even to the most enthusiastic home design/builders. But drawing your shipping container house floor plan and developing the conceptual design, is where the good stuff starts. For real. Earlier, we said we were going to explore how shipping containers are a perfect fit for the design build process. The floor plan is a great example. The 8′ width of a shipping container is roughly a small room. Arrange two containers along their length, remove some corrugation, reinforce, and you’ve got a medium to large room. Remove all the interior corrugation, reinforce, and you have the equivalent of a New York City industrial loft. Containers are “design placeholders” for the perimeter and interior of your home. They allow you to easily conceptualize the interior space and building massing, simultaneously.

Buy a tape measure. Even if you have one. A new one. Make sure it has really good action. That it fits well in your hand, and compliments your attire. It will be your new favorite accessory. Start measuring things. Everything. Measure rooms, furniture, circulation/open space. When you are thinking about dimensions of rooms for your shipping container floor plan and not sure what they should be, go measure a space that works and is comparable in size. Measure some more.

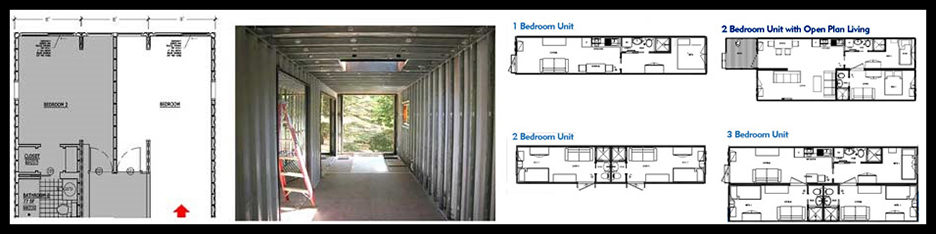

Before you start drawing and sketching, make a wish list of all the functional elements. A schedule of all the square footage components including bedrooms, baths, kitchen, dining room, living spaces, garage, etc. Whatever that total square footage is, multiply it by a factor of 1.3-1.5 to add circulation/open space. Divide that by 320 and you know how many 40′ containers to use. This is your starting point. Get some grid and trace paper. Floor plan software is readily available, but stick low tech for the conceptual sketches. A template file of containers and interior elements is available here to download. Templates like the “Twin 40′ Container Layout” and “Typical Interior Design Elements” pictured above are in the sheets. They are all scaled equally so you can mix the interior elements with the containers and quickly work some simple floor plans. Houses and apartments in dense urban areas are very small. The average total floor area in a Japanese home is 1,020 square feet (three 40′ containers). This should be an additive as well as a reductive process. You want to add to your wish list so you can incorporate/include as much as possible in your shipping container home, but you also want to edit. You can do a lot more with less spatially by introducing sunlight, compacting storage/service spaces, and combining/weaving together program elements. There are many example in the RSCP – Shipping Container Architecture Showcase section that illustrate how shipping container homes feel both intimate and expansive. The Shipping Container Home Floor Plans section also has some example floor plans.

Conceive It Checklist:

- Review site and soil bearing capacity.

- Check for zoning restrictions.

- Determine maximum budget.

- Review site servicing requirements.

- Determine the binding code and review.

- Determine required professional services.

- Prepare project budget.

- Detail all program requirements – number of bedrooms, baths, home office, etc and determine rough square footage of each.

- Develop schematic design – including container massing configuration, floor plans, and elevations.

- Locate local or regional shipping container re-sellers and shops capable of performing modifications and interior fit-outs.

Focus It.

DEVELOP YOUR DESIGN TO A LEVEL OF DETAIL NECESSARY TO WORK OUT A CLEAR, COORDINATED DESCRIPTION OF ALL ASPECTS OF THE PROJECT. DERIVE ALL CONSTRUCTION, PERMITTING, AND BUILD DRAWINGS AND DOCUMENTATION. DETERMINE FINAL BUDGET.

By now, you should have a good sense of your site, your budget, and a rough conceptual design for your shipping container home. You should also be well acquainted with containers. If not, have a look at the RSCP™ CONCEIVE IT section for preliminary and general information for the build, look at the Everything About Containers link for detailed info on shipping containers.

‘Focus It’ index:

Designing Your Shipping Container Home

Foundation

Finalize building location on site. Remember, flat sites are best as they require minimum excavation and grading. If you are planning a build which consists of more than one container, you should talk with an engineer or contractor early. Foundation costs are potentially very expensive, especially if the bearing capacity of the soil is poor or land substantially sloped.

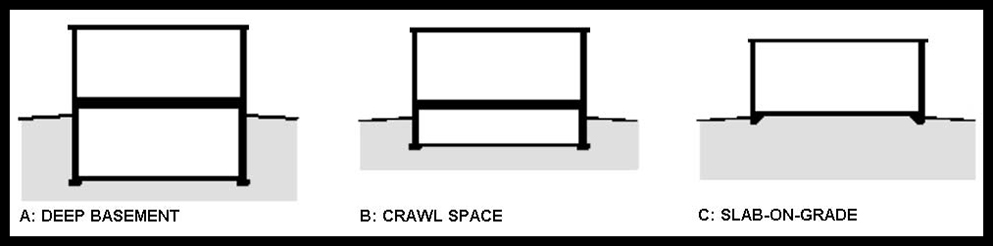

The three basic types of foundations are – full basement, crawl space, and slab-on-grade.

The Shipping Container House Foundations link in the Reference section has more information on foundation options and design.

Shipping Container Home Massing Examples

Shipping Container Home Floor Plans and Interiors

See the Shipping Container Home Floor Plans section for example floor plans.

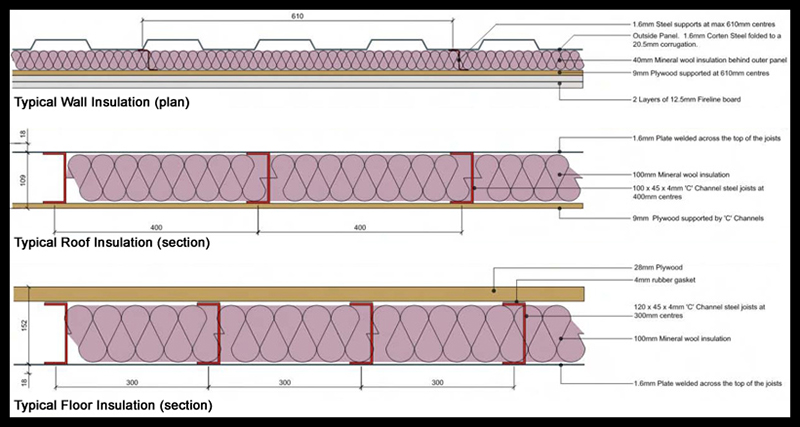

Core Envelope

The exterior walls, ground floor, roof, and glazing make up the core envelope of a building. Energy code compliance and your site’s location, thermal zone, and climate factor strongly here and will determine insulation requirements. Keeping the building warm in the winter and cool in the summer with minimal mechanical system help will do much to drive down monthly utility costs. The conceive it section has information on passive vs. active heating and cooling strategies. These should be reviewed prior to developing/detailing the core envelope. The Passive Solar Design Issues link in the Reference section has good preliminary information on passive design issues to consider while designing/detailing your shipping container home’s core envelope.

The US Department of Energy has a fantastic tool (REScheck) to simplify and clarify code compliance with the Model Energy Code (MEC), the International Energy Conservation Code (IECC), and a number of state codes. You input the square footage of each core envelope element (wall, roof, slab, etc.) and project location. This will determine the binding energy code and allow you to play with different R values (insulation levels) until the envelope design is in compliance and thereby setting the required R-values. Even if your project is small or not subject to energy code compliance, the REScheck exercise is worth the time.

The R-Value Table in the Reference Documents and Details section to the right that has different assembly R-values. Once you know the required R-values for the core envelope elements you can begin detailing. For illustration, consider a cold climate that requires an R-30 value for exterior walls. This could be achieve with batt (R 3.25 per inch ~ R30 would require 9-10″), foam panels (R 5 per inch ~ R30 would require 6″), and standard spray foam (R 6.75 per inch ~ R30 would require 4.5″). The Insulation link in the Reference section has more detailed information on insulation requirements, assemblies, and types.

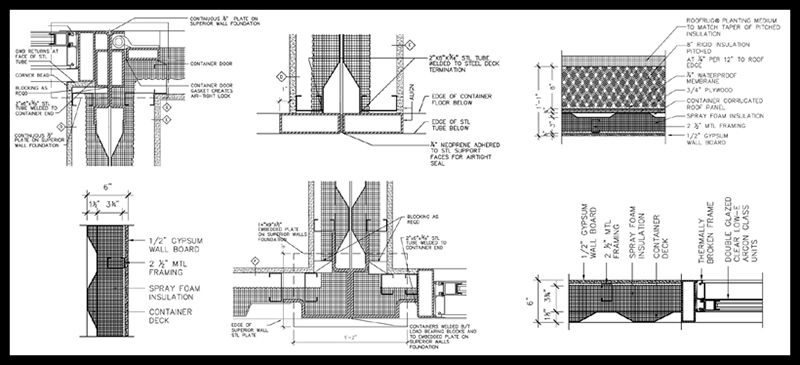

Plan and Section Details

Typical plan and section details including floor, roof, walls, glazing, and container connections can be viewed at the Shipping Container Plan and Section Details link.

Utilities and Mechanical

Utilites –Water supply and sewage, electricity, natural gas, and telecommunications/fiber optics.

Mechanical – Air circulation and temperature regulation.

Drawings and Documentation

The drawings of a typical home construction project evolve through each of the design milestones – Conceptual/Scheme Design, Design Development, Permitting, and Bid/Construction Documents. Conceptual/Scheme Design and Design Development drawings are important to develop the necessary design, floor plans, elevations, and the budget square footage takeoffs. Typically, they are a communication tool between the designer and client as they vet through the design of the home. If you are the designer, you will develop these drawings loosely yourself as you outline/document the design. You can use hand sketches or utilize one of the many consumer modeling and drafting applications. But, they are for your own reference and not necessary for filing.

Permitting Drawings

If for what every reason you are not subject to any building department/jurisdictional approval (very rare) you will not need to assemble a Permitting Drawing set. If you are, which is most cases, first thing to do is call the building department and get a permitting submittal checklist. Things typically required will be plans (site, foundation, floors, and roof), elevations, land survey, water treatment (septic and run-off), energy code compliance, structural drawings, and soils report. Also make sure to check which of these documents will need to be stamped by a licensed professional.

Bid and Construction Drawings

Contract Documents. They should include drawings and specifications for all components and systems of the building. A complete set of Contract Documents provides a comprehensive, fully coordinated set of construction documents and specifications that the contractor uses to determine a guaranteed maximum or lump sum price, obtain necessary permits, coordinate with factory for modular components, and construct the project. Even if you are planning on taking on the construction yourself or managing the project through sub-contractors, you should put together as detailed and extensive set of construction documents as possible. Putting the construction documents together will help tremendously in understanding the design and verifying the projected budget prior to construction.

Build Strategy

Regardless if you are going to bid the project out to general contractors (GC) or build yourself, you should speak with as many potential GC’s as possible throughout the design process. Having done this prior to bidding the project will do three things; help get accurate pricing for budget development, assemble a list of general contractors to bid competitively for the project (if you are not building yourself), and problem solve the design.

If you go the GC route, there are fundamentally three project delivery methods: Design/Bid/Build, Construction Management, and Design/Build. The different methods are distinguished by the way the contracts between the Owner, the Architect (if there is one), and the Contractor/Factory are formed and the technical relationships that evolve between each party inside those contracts. Typically, there is no single “best” method for all projects, and no method delivers fastest, cheapest, and highest quality simultaneously. What distinguishes each is the amount of design information and drawings available prior to construction and whether the build price is fixed or relative to actual costs.

The design and manufacturing of shipping container homes is a viable alternative to conventional construction for many reasons, but despite a strong showing of successful container projects, building with shipping containers is still in it’s early stages. From the design perspective, there are many design entities with “Kit” shipping container home offerings. These however, are very far from turnkey. Virtual none of the “design entities” have shop/manufacturing capabilities. The ones that do, have very small custom shops with limited output which is highly customized and high in price. From the manufacturing perspective, there are more and more factories/companies building with containers. Typically, they have a “stock” catalogue of very base shipping container home designs to purchase turnkey. Some can provide customized solutions (design to your specs), at higher cost points.

Ultimately, whether to hire a general contractor or build yourself depends on – the complexity of the project, your skill and/or experience in building, how much time you have to devote, expected level of finish or craftsmanship, and budget.

Focus it Checklist:

- Foundation Design

- Develop floor plans and elevations

- Determine Structural Design and Container Modification Requirements

- Envelope/Core Shell Detailing

- Figure out Energy consumption

- Investigate passive design moves to improve thermal performance

- Interior Fit-out development

- Prepare Mechanical and Electrical Design

- Outline Material Specifications

- Outline Lighting and IT Requirements

- Outline Build Strategy (think about whether you are going to act as general contractor or a higher builder).

- Outline Procurement Strategy (what level of container modification and fit-out will be done at factory and on site).

- Prepare Construction Documentation (both Architectural and Structural)

- Prepare Mechanical and Electrical Documentation

- Finalize structural design criteria

- Coordinate Preliminary Plan Review with building official

- Coordinate documentation for manufactured components

- Coordinate documentation for potential contractors

- Prepare final specifications

- Prepare final budget

Action It.

BUILDING YOUR SHIPPING CONTAINER HOME.

Building a house is no small feet. Even a small one. There are thousands of materials, pieces, and tasks involved. Unless you are a builder or experienced it’s intimidating. But, what containers as perfect modules allow you to do, is simplify the entire process. Think of a typical 1,000 square foot house. Try and work through in your head the total length of timber for the framing, square footage of sheathing, number of floor joists required, and ceiling rafters. Can’t do it. Not too many can. Now think about that 1,000 square foot house made out of shipping containers. It’s 3 forty foot containers. By reducing the house into 3 base component pieces (modules), it’s much easier to understand, design, and build.

Building a shipping container home is an exciting and innovative endeavor. However, navigating the construction process can feel overwhelming. This portion of the guide breaks down the key steps involved in finalizing your plans, obtaining necessary approvals, and preparing for construction, ensuring a smoother journey to your dream container home.

Bringing Your Shipping Container Home to Life: A Step-by-Step Guide to the Construction Phase

‘Action it’ index:

Permitting, Bidding, and Pre-order

Finalizing Construction Documents and Permitting

The foundation of any successful build lies in detailed and accurate construction documents. These documents serve as the blueprint for your project, outlining every aspect from structural integrity to electrical and plumbing layouts. This stage involves:

- Completion of Construction Documents: Working with your architect or designer, finalize all construction documents, including architectural plans, structural engineering drawings, mechanical, electrical, and plumbing (MEP) plans, and energy efficiency calculations. These documents must meet local building codes and regulations.

- Submission to Building Authority: Once finalized, submit your complete construction document package to the local building authority for review and permitting. Be prepared to pay associated permit fees.

Securing Factory Pricing and Engineering

With approved or near-approved construction documents, you can now engage with the container modification factory:

- Submittal for Pricing and Engineering: Submit your construction documents to the chosen factory. They will use these documents to provide a detailed cost estimate for the container modifications, including cutting, welding, insulation, window and door installations, and any other customizations. The factory will also conduct their own engineering review to ensure the structural integrity of the modified containers.

Navigating Clarifications

Inevitably, questions will arise from both the building authority and the factory. Be prepared to:

- Address Clarifications: Promptly respond to any requests for clarification from the building authority regarding your construction documents. Similarly, work closely with the factory to address their questions about the design and ensure a clear understanding of the project scope. Clear communication is crucial at this stage to avoid delays.

Obtaining Permits

After addressing all clarifications and revisions, the building authority will issue the necessary permits.

- Permit Acquisition: Once approved, collect your building permits. Do not begin any construction until you have obtained all required permits. Display these permits prominently at the construction site.

Engaging Contractors

With permits in hand, you can now finalize your contractor team.

- Submittal to Contractors: Distribute the complete construction document package to general contractors and subcontractors for bidding. Ensure they have a clear understanding of the project requirements and timelines. Carefully review bids and select qualified professionals with experience in container home construction.

Ordering Your Container Modules

The final step before construction begins is securing your container modules.

- Purchase Order Execution: Once you have finalized the pricing and engineering details with the factory, execute the purchase order for your container modules. This legally binds the factory to deliver the containers according to the agreed-upon specifications and timeline. Ensure the purchase order includes details about delivery schedules, payment terms, and quality control measures.

The Build

Site Work

- Begin grading work including any required excavation for foundation, utilities, storm water management, and septic.

- Bring required utilities to site.

- Install septic system and any storm water management system if required.

Foundation

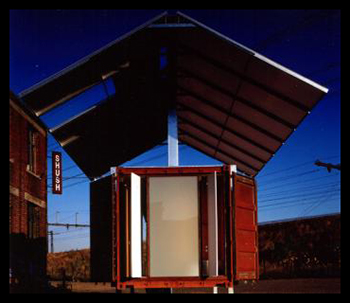

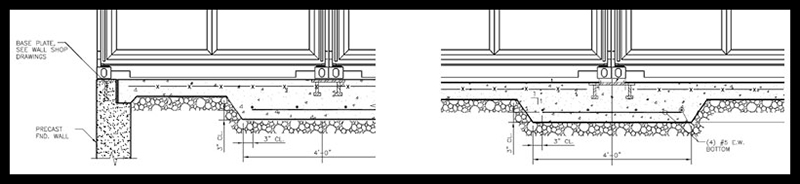

The foundation shown below is a typical slab on grade application for a 1000sf (three 40′ containers) shipping container home design. There is a 24′ x 40′ perimeter foundation wall made from precast concrete panels, but could easily be cmu block or poured concrete. The perimeter was excavated and trench filled with gravel (for drainage). The precast panels were dropped in via a crane and tied together. The panels included insulation and exterior water proofing membranes added at the factory. Utilities (water, electircal, and gas supply lines) are run to the base of the foundation and then to there respective locations in plan. Foundation walls were then back-filled, soil compacted, gravel added, rebar laid out, and then slab poured.

The Shipping Container House Foundations link in the Reference section has more information on foundation options and design.

Container Modifications

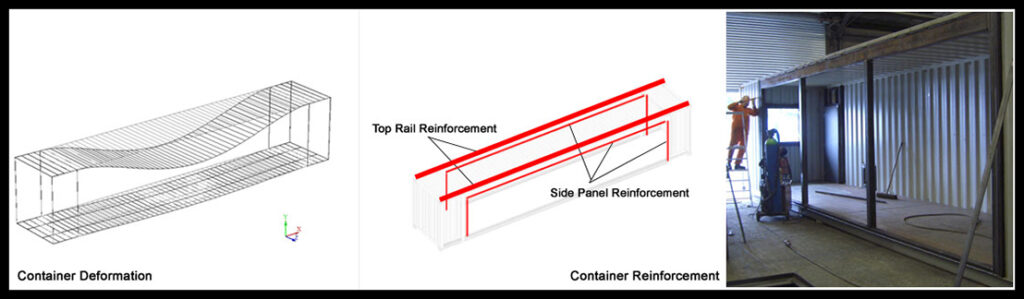

Shipping containers have monocoque bodies. The corrugation panels (roof, sides, and back), floor, purlins, front doors, frame, and rails form an integrated structural skin. They are strong and made to carry floor loads far in excess of what is required for typical home construction. But, when you modify them, cutting holes or penetrating members, they are weakened. Regardless of what level of modification your shipping container home design calls for, it is recommended to review with a structural engineer or architect.

As we said above, when cutting a shipping container or removing any of the paneling, it’s structural integrity is compromised. As an extreme example, consider the removal of all a container’s corrugated paneling along the length of one side (see the images below). Without reinforcement, the container deforms and then fails structurally. As a general rule, whenever you remove portions of the panelized corrugation, steel framing will be required to frame out the opening. In addition, column and roof support will be necessary depending on the size of the opening(s) and roof/wind loads.

Steel cutting, framing, and welding is a large part of shipping container home design and construction. Typically, steel construction is not used much in single family or smaller home design because of expense. Cost of steel vs. wood/light guage framing is substantial and the labor cost for steel vs.carpentry is also higher. To combat this, it is best to have as much of the welding and reinforcing done off-site before setting the containers on site and starting the interior fit-out. Most (if not all) container re-sellers have the facilities to make these modifications. If you don’t have experience in metal work, or are not hiring a general contractor, you should plan on doing most of the container modification work off-site prior to delivery. More information on Cor-Ten steel (the weathering steel shipping containers are made from) is available at the CorTen – Shipping Container Weathering Steel link in the RSCP Reference section.

The Shipping Container Structural Components and Terminology link has more detailed information on the structural components of a shipping container. The Shipping Container Plan and Section Details link has more information on container to container connection details and framing on opening in the corrugation.

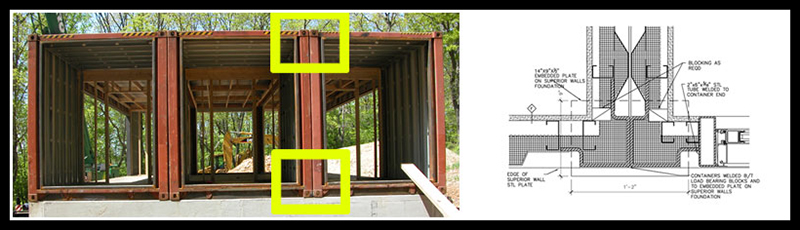

Set and Secure Containers to Foundation and Each Other

When the shipping containers arrive on site, they are crane-lifted one by one onto the foundation, hooked into place, and welded down to marry them completely to the foundation. These heavy-gauge steel containers are so strong—each is designed to carry 57,000 pounds—that they need only be fastened at the corners to hold fast, much as they would be on a ship. In the example above, the shipping container bottom corner blocks are welded to steel plates imbedded in the concrete slab to secure the house to the foundation. All corner blocks are welded to each other to secure the containers to themselves in the image below.

Install windows, exterior doors, flashing, and any skylights.

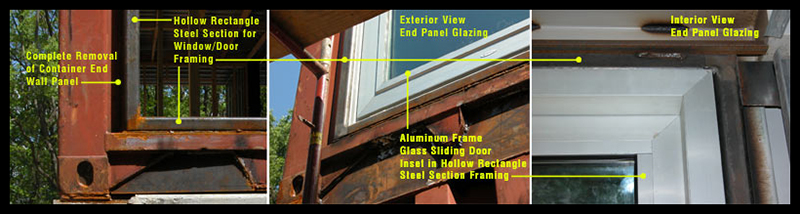

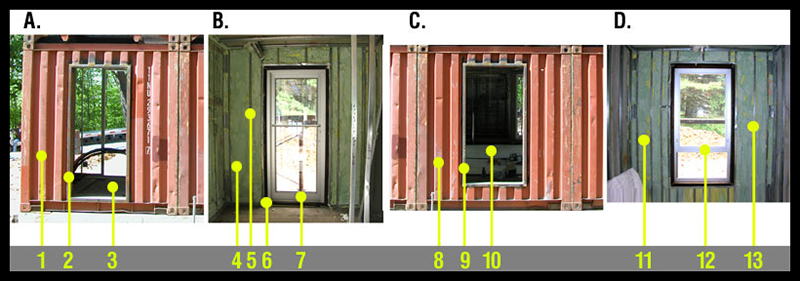

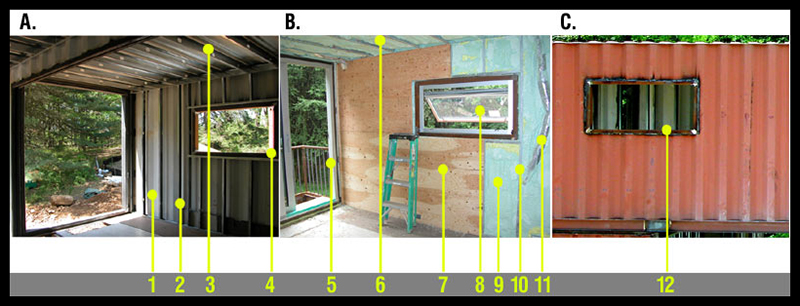

Windows are set into openings that were measured and cut prior to delivery of the shipping containers or roughed out on site. All openings for windows and doors should be framed with a steel section. Hollow rectangle sections work the best, but an L section will work as well. Images below show openings for sliding door systems in the end and sidewall panels of a container. The Shipping Container Plan and Section Details link has construction details for window/door framing, flashing, thermal breaks, and glazing.

Install interior framing, insulation, heating and cooling systems, plumbing, electrical, and rough out all fixtures.

Supertherm insulative coating, is sprayed on both sides of the remaining container walls. Supertherm is a high-performance, four-part ceramic coating that carries an R value of R-19 and adheres to the steel surface of the shipping containers. A ½- inch plywood floor over the existing ¾- inch plywood sub-floor is installed. Metal hat channels for wiring are run along the walls and vertical support beams are secured. Metal studs and drywall are used for interior partition walls. Once insulated, the existing container walls are faced in drywall for finishing.

Install fixtures.

Finish grading and landscaping.

Inspection and Sign-off

- Staged inspections through the build with contractor and building official – foundation, plumbing and electrical, architectural, and fire.

- Put together final check/punch list for contractor.

- Review punch list with contractor.

- Final inspection with building official for certificate of occupancy .

MORE INFORMATION, ARTICLES, DETAILS, WORKSHEETS, AND PLANS ADDED WEEKLY. SO PLEASE CHECK BACK. IF YOU HAVE QUESTIONS OR AN ARTICLE TO CONTRIBUTE OR PROJECT TO SHOWCASE PLEASE GO TO RSCP™ GET HELP LINK.